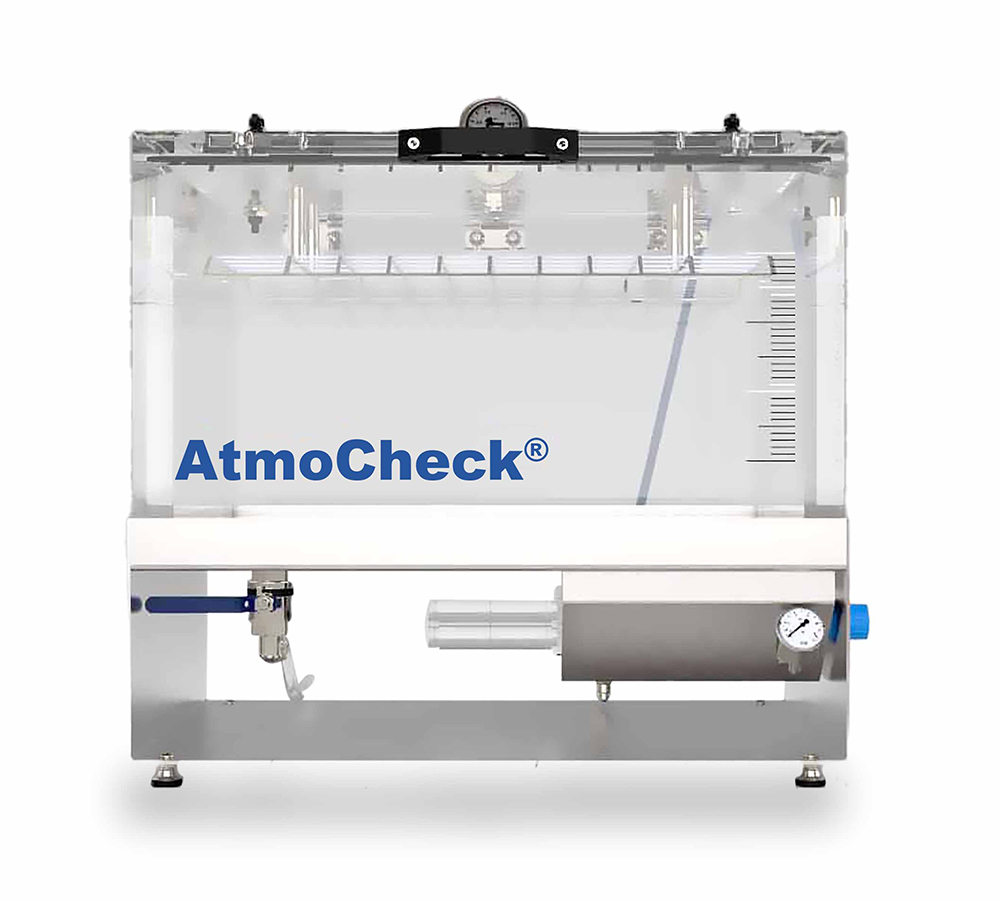

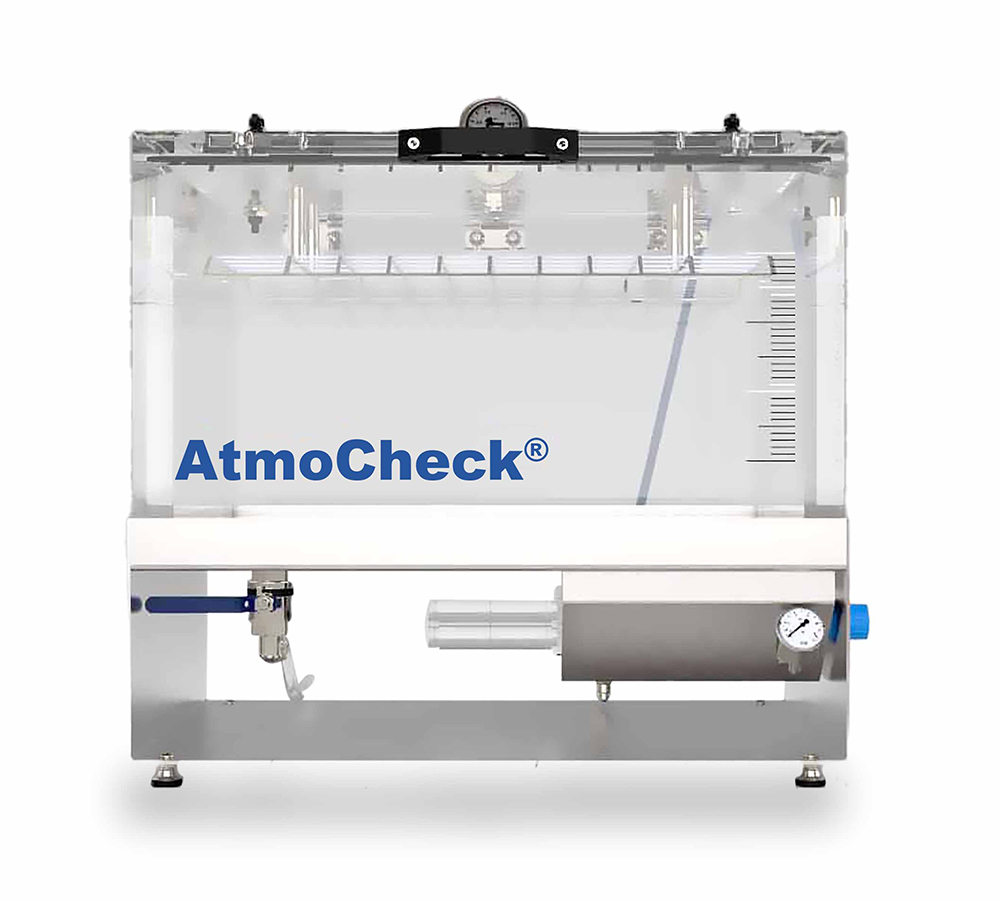

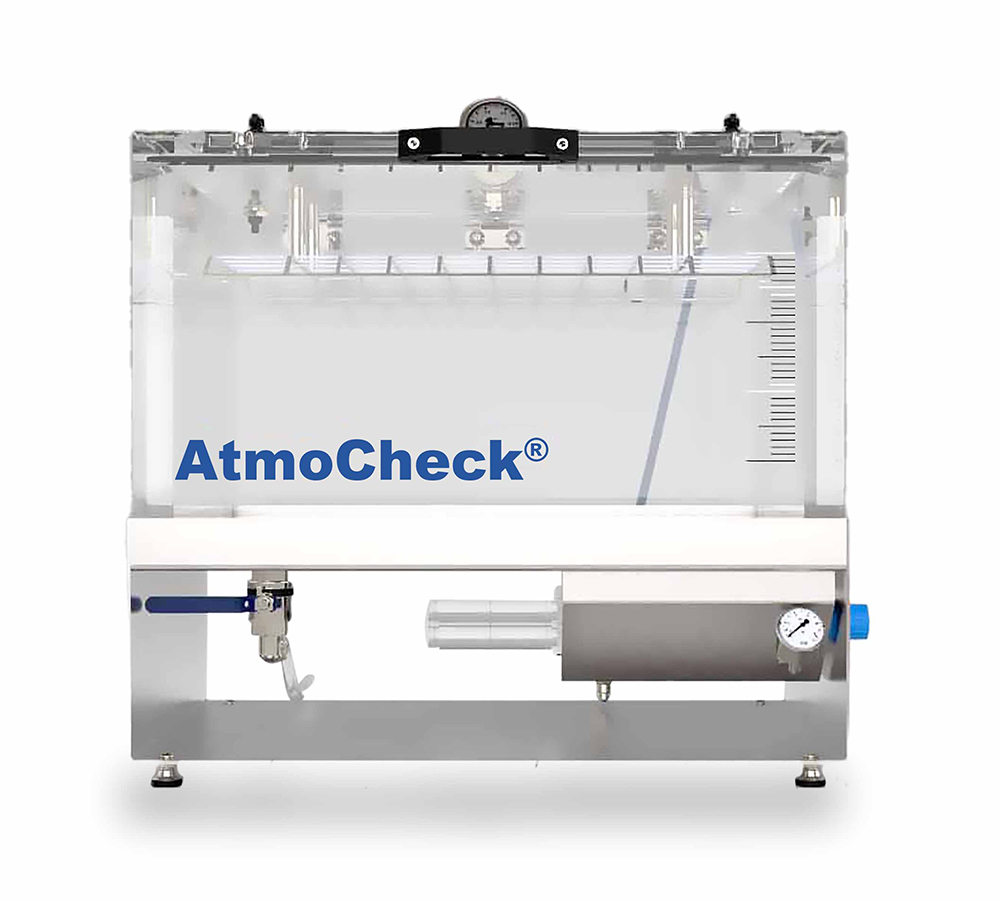

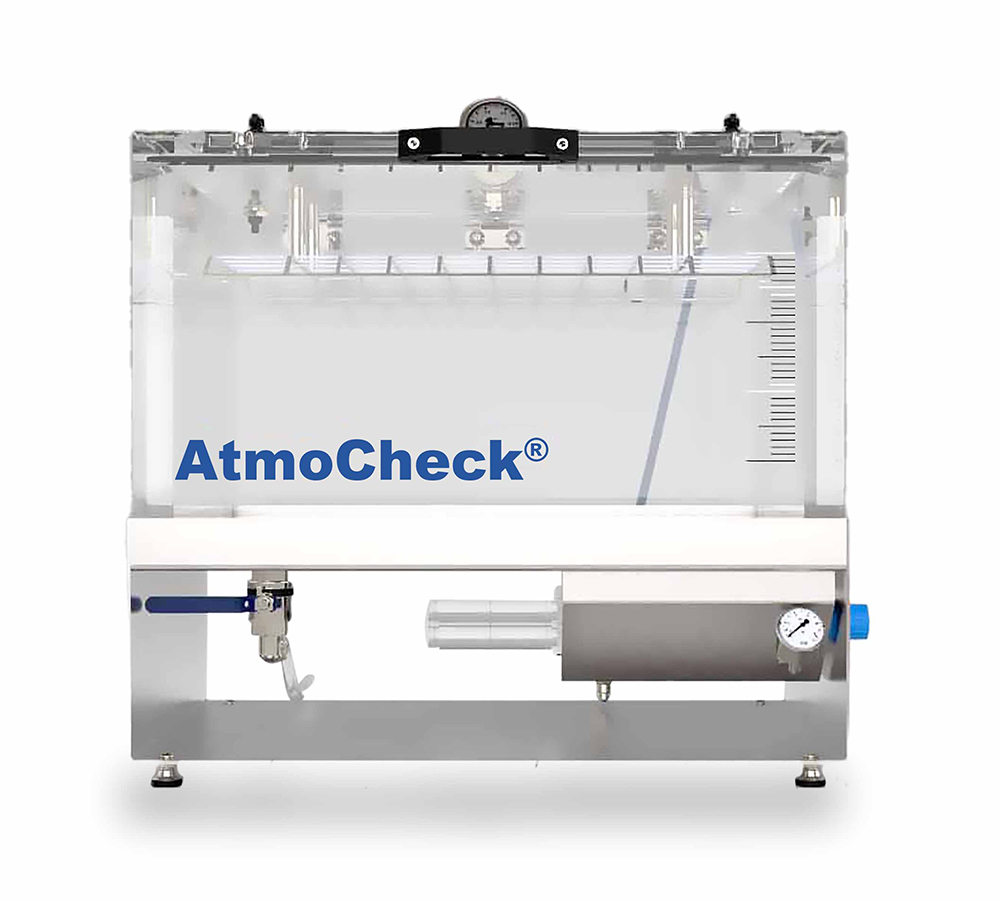

AtmoCheck® LEAK TEST

AtmoCheck® LEAK TEST

Different packaging has different requirements.

With our AtmoCheck® LEAK TEST we can support you to test and ensure the integrity of your packaging.

For many different packaging types and requirements, completely without operator

training.

Test Methods

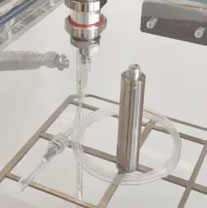

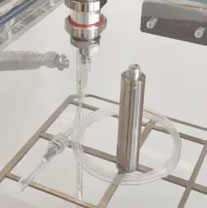

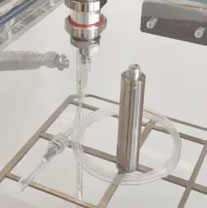

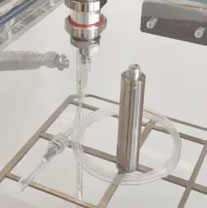

- Leak Detection - Seal Integrity Test

- Burst Test

- Package Pressure Test

- Dry Chamber Leak Test (Liquid Product)

- Vacuum Packaging Test

All highlights at a glance

- Easy to use, one hand operated, intuitive system

- Suitable for all flexible and rigid packs, MAP and vacuum-packed products (with optional vacuum kit)

- Visibility of the leak helps to determine and eliminate the cause of the the leak

- Test is made in less than 30 seconds

- Standard chamber inner size 520x340x225 mm (WxDxH) (45kg empty)

- Chamber is made from genuine PLEXIGLASS material and certified technology

- Low maintenance Compressed air venturi nozzle as standard (no electrical connections)

- Electrical vacuum pump (optional)

- Water drains for easy tank maintenance

- Automated or manual control

- Can also be used for height simulation

- No calibration necessary

- Easy installation and commissioning

Typical Applications

- Food Packaging

- Medicine and Pharmaceutical Products

- Package development

- Automotive industry, industrial applications

Package Types

- Doy-pack

- Pillow bag

- Flow-pack

- Tray

- Thermoforming

- Premade bags

- Vacuum pack

- Bottle

- Cup

- Cans

Similar Items